Steam Surface Condensers

The Backbone of Power Plant Performance

In every steam power plant, the condenser plays a critical role, quietly driving efficiency, protecting turbine performance, and safeguarding overall reliability. Without it, even the most advanced power generation systems would face higher heat rates, reduced output, and costly downtime.

At TEi, we understand that your condenser isn’t just another piece of equipment, it’s the heart of plant efficiency. That’s why we’ve dedicated decades of engineering innovation to designing condensers that deliver maximum thermal performance, mechanical integrity, and long-term dependability. From new builds to retrofits and modular upgrades, our solutions are tailored to meet the evolving demands of today’s power producers.

When uptime matters most, TEi condensers provide the efficiency, reliability, and peace of mind that plant operators around the world count on.

Steam Surface Condensers

Engineered for Maximum Efficiency and Reliability

The steam surface condenser is a vital component in steam power plant performance, directly impacting heat rate, turbine backpressure, and overall plant availability. At TEi, our condenser designs represent decades of advanced thermal and mechanical engineering, with a focus on improving performance, reducing forced outages, and extending equipment life.

Whether for new construction, retrofit, or performance upgrades, TEi surface condensers are engineered for optimal functionality, longevity, and easy integration into existing systems. Our designs also accommodate a range of space-saving configurations and turbine exhaust layouts to suit your plant’s specific footprint.

Every unit is engineered to:

- Optimize tube layout and surface area for better heat transfer

- Distribute steam uniformly to eliminate hotspots and pressure imbalances

- Minimize pressure drop and destructive steam velocities

- Enhance deaeration and reheat system performance

- Efficiently remove non-condensable gases

- Control subcooling for improved condensate quality

Our mechanical design approach prioritizes reliability, safety, and maintainability:

- Robust protection against tube vibration and condensate contamination

- Controlled thermal expansion and stress management

- Heavy-duty construction with steam path optimization

- Designed for straightforward field assembly and installation

- Force and moment analysis of condenser panels available for customer use

- Engineered safeguards for high-energy fluid exposure

- Minimized tubesheet stress and tube loading for long-term performance

From fossil and combined cycle plants to nuclear and industrial facilities, TEi steam surface condensers are trusted worldwide for their superior design, durability, and performance. When efficiency and uptime matter, TEi delivers.

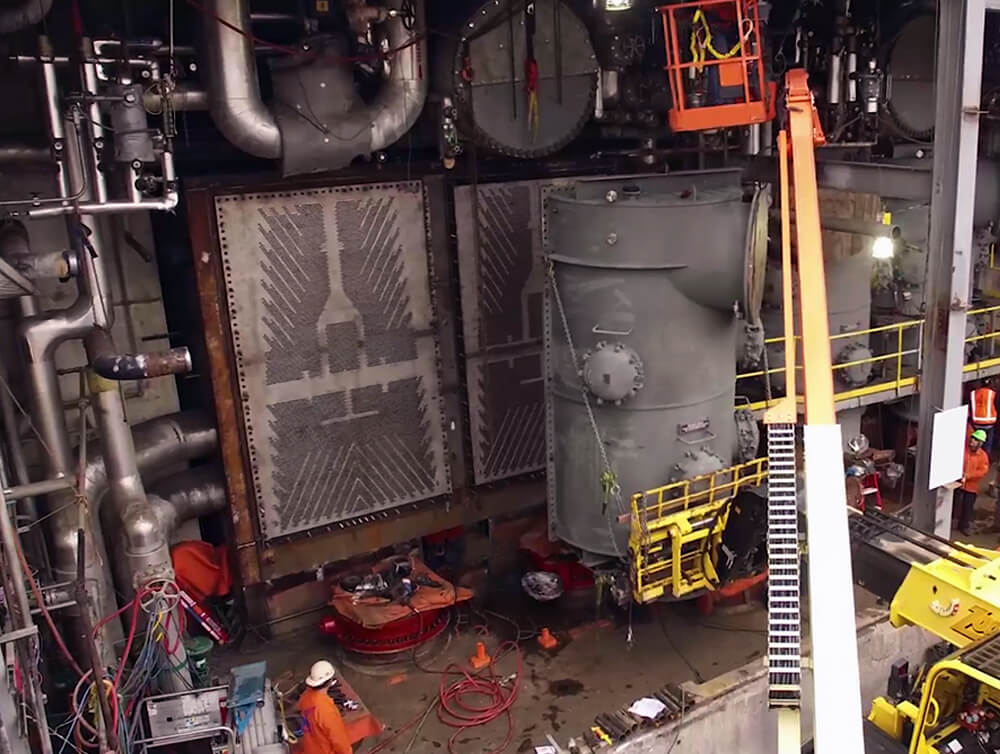

Modular Changeout Solutions for Steam Surface Condensers

Efficiency. Precision. Performance.

As a leader in heat transfer technology, TEi offers modular changeout solutions that redefine what’s possible in steam surface condenser refurbishment with the ability to provide this work turnkey. Our modular approach provides a fast, cost-effective alternative to traditional retubing, enabling you to upgrade, optimize, and extend the life of your existing condenser system with minimal downtime.

Modular changeouts are not just maintenance, they’re an opportunity to enhance thermal efficiency, improve reliability, and meet the evolving performance demands of today’s power generation landscape.

Leveraging advanced metallurgy, refined welding techniques, and decades of R&D, TEi has developed a highly efficient modular condenser replacement system. Our technology draws from industry-leading expertise in titanium fusion welding and complex condenser projects, delivering unmatched precision and long-term performance.

We serve a broad spectrum of power producers, including fossil, nuclear, solar, biomass, and co-generation facilities, and design around diverse turbine exhaust layouts and enhanced deaeration requirements to optimize plant performance.

Reuse Existing Shell & Connections

- Retain external interfaces for minimal disruption

- Modify and upgrade internal structures to meet new performance criteria

Factory-Aligned Modules

- Cages pre-built and aligned at our facility

- Accelerated installation time during outages

- Delivered directly to site, ready for integration

Enhanced Manufacturing Efficiency

- New support plate drilling patterns reduce lead time

- Matching replacement plates ensure seamless alignment

Turnkey Execution with TEi Expertise

- Complete retrofit and installation managed by TEi Heat Exchanger Services

- Trained and certified teams on call 24/7/365

- Full range of emergency and planned maintenance services

A steam surface condenser is essential to plant efficiency, don’t trust its upgrade to anyone else. TEi’s modular changeout solutions combine speed, precision, and innovation to get your plant back online faster and running stronger.

Let us help you modernize your condenser and unlock peak performance with confidence.

Need More Info?

We Can Help!

Whether you need more information or would like to discuss your next project, we look forward to speaking to you.