Proven Thermal Solutions for

the Process Industry

With decades of experience and a legacy built on innovation, the Struthers Wells™ product line, offered through TEi, continues to set the standard for performance and reliability in the process industry. From petrochemical plants to chemical processing facilities and refineries, our fired heaters and heat recovery solutions are engineered to meet the rigorous demands of today’s high-performance environments.

We specialize in delivering robust, custom-engineered thermal systems designed to increase efficiency, extend service life, and optimize plant operation under extreme conditions.

PROCESS

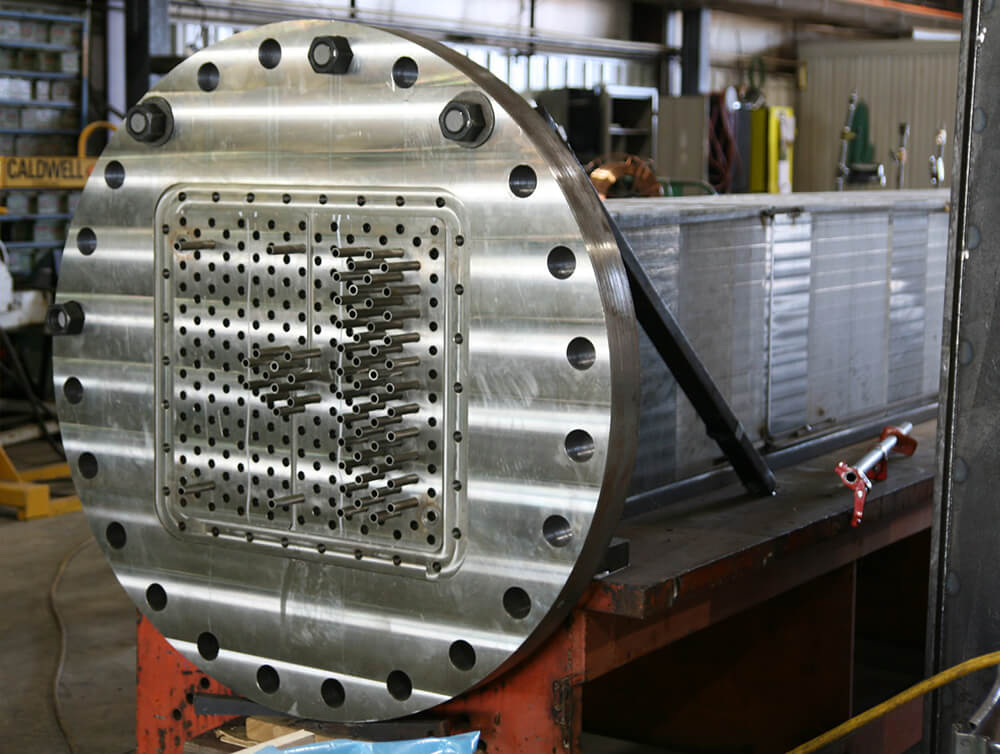

Shell & Tube Heat Exchangers

Robust shell-and-tube heat exchangers built to TEMA (Tubular Exchanger Manufacturers Association) standards — designed for reliable, long-lived performance in industrial duty. Our designs address thermal stresses, erosion, fouling, and maintenance access, providing optimized heat transfer in rigorous process environments.

TEi Struthers Wells™ can design and supply the kettle type reboilers with integral steam separation for low or medium steam pressures.

Shell and tube heat exchangers used on hydro-cracking and hydrodesulfurization require special closure design because of requirements imposed by the process licensor: Chevron & Union Oil. In 1968, Struthers Wells participated in the design of a special heat exchanger for a major oil company to use in a hydrocracking process. Since then, Struthers Wells has adapted the basic concept of the breech lock closure to a number of heat exchangers with innovative new features that greatly improve closure reliability, including:

- Fully removable bundle

- Minimum number of leak paths to the atmosphere of high hydrogen content at elevated temperatures

- Tightening the internal gasket in service, eliminating leakage between shell and tube side fluids in feed/effluent, increasing the efficiency of the process

Our improvements to the original concept have resulted in dependable performance with benefits such as:

- No fluid pressure on the mechanical threads, thus avoiding hoop stresses and radial expansion at the threads

- Compensation for differential thermal expansion when temperatures of joint components vary

- Improved ACME thread that optimizes pitch and prevents potential binding issues

- Improved horizontal installation prevents scraped-off metal chips that can cause leaks in shell-to-tubesheet gasket

- Forces on the threads are purely mechanical

High-performance heat transfer systems for molten salt applications in small/modular reactors or solar thermal plants. Our designs handle extreme temperatures, maintain salt chemistry integrity, and ensure safe, efficient heat exchange in closed or open loops.

PROCESS

Waste Heat Boilers

High-efficiency water tube heat exchangers built for demanding service. With rigorous thermal design and proven pressure handling, these units are ideal for steam, feedwater, and process heating duties in power and industrial settings.

Heat transfer units tailored to process gas streams—whether for heating, cooling, or recuperation. Engineered for gas composition, temperature swings, fouling potential, and pressure drop constraints, offering dependable performance in gas-phase duties.

Specialty heat exchangers for extreme service: nuclear reactor circuits, high-temperature process gas, or delayed coker duty. These units are engineered for severe temperatures, aggressive fluids, and tight safety and reliability requirements.

PROCESS

Fired Heaters

Complete thermal fluid (organic, synthetic, or molten salt) heating and heat transfer systems. We design, supply, and integrate systems for stable temperature control, efficient circulation, and reliable operation in industrial applications.

Custom-designed process furnaces and fired heaters for high-temperature thermal conversion. With modular construction, precise burner control, and integration with waste-heat recovery, our furnaces offer efficient, low-emission performance.

PROCESS

Sulfur Recovery Trains

Designed to cool process gases above 2600°F (1400° C) and pressures above 3,000 psi (210 kg/cm2), Struthers Wells™ waste heat boilers generate high quality steam to pressures higher than 2,100 psi (150 kg/cm2) for steam generation rates up to 500,000 lb/hr (230,000 kg/hr). Designs include:

- Waste heat boilers

- Single shell

- Dual compartment

- Internal by-pass

The flexible-supported-stayed-thin tubesheet design pioneered by Struthers Wells is typically 1” (25mm) thick. This allows good cooling by the water on the rear face lowering the tubesheet metal operating temperature. Tubes act as stays, remain at the same temperature, so the sheet stays flat. Flexible connection of tubesheet to shell allows for expansion and gives good fatigue resistance. In addition, the full thickness tube-to-tubesheet weld provides tubesheet integrity, eliminates crevice corrosion on the water side, and ensures equal metallurgy in the weld and on the tubesheet.

Struthers Wells™ waste heat boilers are typically supplied with an overhead steam drum for water and steam circulation with a large recirculation rate to ensure effective cooling. The steam drums are equipped with two stage phase separation systems to provide high purity steam which is frequently used to generate power through steam turbines. Internal cyclone separators and demister pads are used for steam-water separation. Water and steam quality are in accordance with ABMA Standards. The drums fabricated to ASME or other codes are matched to the Waste Heat Boiler requirements and fitted with suitable instrumentation to ensure safe and smooth operation.

Custom-engineered piping systems designed to integrate seamlessly between key process units. Optimized for high‐temperature, corrosive, or high-pressure flow paths, our interconnecting piping delivers precise fluid routing, minimal thermal losses, and reliable long-term performance.

Robust condenser designs tailored for sulfur recovery environments. We deliver high-purity condensation of sulfur vapor streams, with corrosion-resistant materials and thermal control engineered to match the sulfur dew point and process conditions.

PROCESS

Condensers

The steam surface condenser is a vital component in steam power plant performance, directly impacting heat rate, turbine backpressure, and overall plant availability. At TEi, our condenser designs represent decades of advanced thermal and mechanical engineering, with a focus on improving performance, reducing forced outages, and extending equipment life.

Whether for new construction, retrofit, or performance upgrades, TEi surface condensers are engineered for optimal functionality, longevity, and easy integration into existing systems. Our designs also accommodate a range of space-saving configurations and turbine exhaust layouts to suit your plant’s specific footprint.

Our mechanical design approach prioritizes reliability, safety, and maintainability:

- Robust protection against tube vibration and condensate contamination

- Controlled thermal expansion and stress management

- Heavy-duty construction with steam path optimization

- Designed for straightforward field assembly and installation

- Force and moment analysis of condenser panels available for customer use

- Engineered safeguards for high-energy fluid exposure

- Minimized tubesheet stress and tube loading for long-term performance

As a leader in heat transfer technology, TEi offers modular changeout solutions that redefine what’s possible in steam surface condenser refurbishment. Our modular approach provides a fast, cost-effective alternative to traditional retubing, enabling you to upgrade, optimize, and extend the life of your existing condenser system with minimal downtime.

Modular changeouts are not just maintenance, they’re an opportunity to enhance thermal efficiency, improve reliability, and meet the evolving performance demands of today’s power generation landscape.

PROCESS

Feedwater Heaters

Compact. Efficient. Purpose-Built.

TEi has designed and manufactured over 2500 low pressure feedwater heaters with all types of tube materials and configurations. Our Vertical Channel Down (VCD) designs reduce footprint and streamline piping layouts, while offering easier bundle access and simplified maintenance. Each LP heater is custom-built to meet specific site conditions and thermal demands.

Advanced Design for Demanding Conditions

High pressure feedwater heaters operate in extreme environments—often above 1000 psi—and require proven engineering solutions. TEi delivers with sophisticated designs that handle severe superheat, complex flow paths, and high-energy fluid dissipation. We specialize in optimizing performance under both normal and overload conditions through robust mechanical designs and advanced thermal modeling.

Need More Info?

We Can Help!

Whether you need more information or would like to discuss your next project, we look forward to speaking to you.